Graymills peristaltic ink pumps—engineered exclusively for flexographic and gravure printing—set the standard for efficiency, reliability, and easy maintenance. Designed for quick color changes, short-run flexibility, and compatibility with a wide range of inks, coatings, and adhesives, these patented “tube” pumps deliver smooth, consistent flow with minimal downtime. Built in the U.S. and proven in pressrooms worldwide, Graymills peristaltic pumps provide the performance, durability, and control today’s printers demand.

Unlike conventional peristaltic pumps adapted from other industries, Graymills peristaltic or “tube” pumps are engineered specifically for flexo and Gravure printing applications and have received U.S. Patent number 5,630,711.

Graymills peristaltic pumps easily accommodate a wide variety of fluids form inks and coatings to adhesives – water, solvent, and UV/EB.

These innovative design features are especially valuable in the pressroom when short runs require frequent changeover and quick turnaround. Built in the U.S. for reliability, low maintenance, and long life.

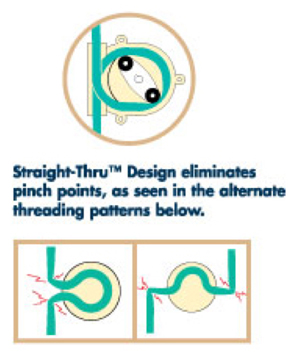

All Graymills peristaltic pumps feature a high output gear motor which combines variable speed and reversibility with essential torque. The steel pump housing, which protects the pump against splashing and damage, has a baked-on hybrid powder coating for a long lasting durable finish. Three swivel lock fasteners quickly release the pump head cover, without tools or loose parts, facilitating a quick tube change. The Graymills head design allows the tube to run “straight-thru” from the bucket to the print deck, eliminating “pinch points” where kinks form that slow the flow and weaken the tube. Dual roller technology combines just two rollers with a longer compression cycle to provide greater flow with fewer rotations. This results in lower friction, reduced tube fatigue and less flow pulsation.

For narrow web flexo and rotary screen applications and light to heavy viscosity inks, coatings, and adhesives (including UV/EB) requiring flow rates of 1.5 GPM or less.

For mid to wide web flexo, gravure, and rotary screen applications and light to heavy viscosity inks, coatings and adhesives (including UV/EB), requiring flow rates of 4.5 GPM or less.

Two peristaltic pump heads powered by a single motor allow the pump’s heads to be individually set to supply or return.

Model PQLM is the model for tough environments. This metal head version of the PQL lasts through long runs, numerous changeovers, and demanding applications. Variable speed control offers adjustable flows which can exceed 4 GPM.

Request a quote or call us today for more information about Graymills